There are two major types of centerfire rifle cartridges available on the market today:

- Those which are loaded with steel, and

- Those which are loaded with brass

This seemingly simple variation has caused a never ending stream of argument, discussion, speculation, and questioning from new and seasoned shooters alike. So, our team set out to test and determine what differences you can expect when shooting brass vs. steel cased ammo in this epic torture test. Complicating the conversation are other variables that typically get lumped into the argument without proper segmentation, such as:

- Different coating options available on the steel-cased ammo (lacquer or polymer)

- The different projectile loadings available (copper jacketed lead, the bi-metal coating that most Russian manufacturers use, etc)

- The different propellant (gunpowder) burn rates

Our team decided to try something ambitious and daunting: to provide the best resource and data available to answer these questions once and for all through objective experimentation and observation.

We realize this is a lofty and borderline arrogant goal. We’ve done our best. Please keep reading to see if you agree.

Brass vs. Steel Cased Ammo Test Summary

- We acquired four identical Bushmaster AR-15 rifles. We chose the Bushmaster MOE Series AR-15 because it’s a widely available, affordable, and mass-market. Our team didn’t want something too cheap and of lower quality or something too expensive and of high quality since our goal is to help the most number of people.

- We acquired 10,000 rounds each of the following ammunition (new production):

- Federal 55gr – Brass-Cased – Copper Jacket

- Wolf 55gr FMJ – Steel-Cased with Polymer Coating – Bi-Metal Jacket (steel and copper)

- Tula 55gr FMJ – Steel-Cased with Polymer Coating – Bi-Metal Jacket (steel and copper)

- Brown Bear 55gr FMJ – Steel-Cased with Lacquer Coating – Bi-Metal Jacket (steel and copper)

- We paired each ammunition type with a specific Bushmaster AR-15 and then fired all 10,000 rounds of it through that particular carbine (except for Tula; more on that below)

- We systematically observed and tested various things, including (more details below):

- At the start: accuracy, velocity, chamber and gas port pressures, chamber cast

- After 2,000 rounds: accuracy, velocity

- At the 4,000 round mark: accuracy, velocity

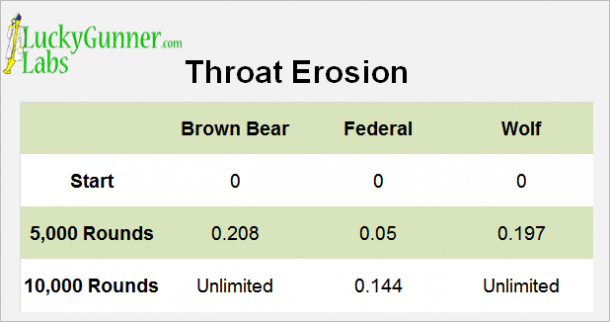

- After 5,000 rounds: throat erosion, chamber cast

- Af the 6,000 round mark: accuracy, velocity

- After 8,000 rounds: accuracy, velocity

- After 10,000 rounds: accuracy, velocity, chamber and gas port pressures, throat erosion, extractor wear, chamber cast, barrel wear

- We logged every malfunction of every rifle-ammo combination

- The rifles were cleaned according to a preset schedule and temperatures were monitored and kept within acceptable limits (more below)

- We sectioned the barrels and otherwise made unique observations after the test was complete

If you’re interested in any of the following, you’ll find observations, data, and further details below:

- What ammunition was most reliable?

- Which ammunition was the dirtiest?

- Which performed better, lacquer or polymer coating?

- What ammunition maintained the highest degree of accuracy throughout the test?

- Which ammunition maintained the most consistent velocity throughout the test?

- Which ammunition caused the most throat, barrel, and extractor erosion/wear?

- What effect did the powder burn rates have on bolt cycling?

- How did the pressure at the gas port vary by ammunition type?

- How did the pressure at the chamber vary by ammunition type?

- Which is cheaper to use, after considering all the costs?

What follows is a mind-numbing heap of charts, tables, graphs, images, and data to catalog the entire test, plus a careful analysis of everything we found. We hope you’ll find it as fascinating as we did. If you’re in a hurry and just want a brief overview, check out the summary video below.

Brass vs. Steel Cased Ammo Summary

Watch our 2 minute video summary.

Past Tests

No public tests offer the depth of information shooters demand

When we considered an undertaking like this, we wanted to investigate what tests others conducted before us. Over the past 55 years, several groups published a variety of tests conducted using the AR-15/M4/M16 platform. We studied as many as possible in order to determine the best course to take.

One of the more notable tests – certainly one of the most discussed – was the Army’s “M4 dust test” of 2007. Much of the public domain information about the test was lacking – were all rifles of new manufacture? Did all firearms use the same magazines? What qualified as a malfunction? How do we define each type of malfunction? What were some of the details relating to how each rifle functioned, such as cyclic rate of fire? We sought to address each of these concerns in our test.

The Naval Surface Warfare Carne conducted a test of the MK18 10.5″ CQBR and presented the results at the 2003 NDIA conference. Although the public domain report is rather concise and also focuses on why the weapon itself was created, it contains a lot of useful data such as throat erosion and cyclic rate. They deliver the total number of malfunctions but don’t provide details like when and how each one occurred. Perhaps this is due to time/length constraints. We borrowed a number of ideas and methodologies from this test, including limits on rate of fire and temperature.

A 2012 collaboration between Tulammo USA and Anderson Manufacturing compared the performance of Federal and Tula ammunition in Anderson Manufacturing carbines. Although malfunctions occurred during the testing, they didn’t publish the number of malfunctions for public consumption.

The Ammunition

For the test, 10,000 rounds each of Federal, Brown Bear, Wolf, and Tula ammunition in caliber .223 Remington were used. Each brand of ammunition used a 55 grain full metal jacketed bullet with a lead core. The Federal 55gr .223 ammunition featured a solid copper jacket and a brass case. The other three brands used a bimetal (steel and copper) jacket and a steel case. Brown Bear coats their steel case ammo in a green “lacquer.” Tula and Wolf coats their cases with a gray polymer.

The Rifles

We used four brand new and identical Bushmaster MOE carbines this brass vs. steel cased ammo test. Specifically, we enlisted four Bushmaster model BCWA3F MOE rifles. Bushmaster manufactured each in Ilion, New York at the same facility where they make Remington rifles.

Upper and lower receivers were of standard design and manufactured with 7075-T6 aluminum via the forging process. Receiver extension tubes were commercial pattern and had six adjustment points; receiver endplates were not staked. Buffers weighed 3.0 ounces and conformed to carbine dimensions. Fire control groups were semi-automatic and trigger pull weight varied between 8 and 10 lbs. Bolt carrier groups were machined for semi-automatic use only; gas keys were properly staked.

Barrels were 16” in length, with all other exterior dimensions matching those of the military M4. We attached front sight bases to the barrels with two taper pins driven from right to left. We parkerized the barrel exteriors after the attachment of the front sight bases.

Gas ports, located at the carbine position, were .058” in diameter. Chambers conformed to 5.56mm dimensions. The rate of twist was 1 turn in 9 inches, and both chambers and bores were chrome lined. Barrel nuts were torqued to inconsistent values: two had been torqued to approximately 5 ft/lbs, while the other two had been torqued within the appropriate range of 30-80 ft/lbs.

Accessories Used

Magpul MOE furniture enabled the attachment of sling mounting points and flashlight mounts from Impact Weapons Components designed for the MOE stocks and handguards. The sling mounting points and flashlight mounts remained attached to the firearms without issue throughout the entire test. However, flashlights of the correct diameter installed in the mounts in accordance with provided instructions did not stay in the mounts. Excessive tightening of the mounts’ tension screw did not fix the problem. So, we set aside the flashlights for the duration of the testing.

We used Aimpoint CompM3 in GDI mounts as well as the EOTech 552 and XPS 2-0 for optics during the high volume shooting portion of the test. Backup sights were Magpul MBUS. One MBUS sight cracked and fell off of the carbine to which it was attached. We believe heating and cooling cycles negatively affected the polymer material and caused the cracking.

Excessive upper receiver heat did cause thermal discoloration of and cosmetic damage to the EOTech sights. Also, one CR123 battery in the XPS 2-0 ruptured – possibly due to heat. Both EOTechs, as well as the Aimpoint, remained functional at the end of the test. The manufacture date of the 552 was April of 2005; prior to the test, we replaced its battery spring “grommets” with a newer design. This markedly improved battery life.

We used charging handles during the test that included the standard AR-15 type, the BCM/Vltor Gunfighter, and the Rainier Arms/AXTS Raptor.

We fired the majority of rounds (over 20,000) with the Raptor charging handles installed in various weapons. Our testing team did not encounter any functional issues with any charging handle used during the test. Our team noted no practical differences between the aluminum and steel latches of the various charging handle types. Most shooters who used the Raptors commented that they appreciated the ambidextrous design during manipulations of the firearms, especially during clearing.

We do not believe our use of these accessories had any functional impact on the weapons. You should not be construe the inclusion as true modifications. With one exception, the results of this test reflect the performance of the carbines in the condition in which they were removed from the box. That exception involves improper torque values that our team corrected in two of the four test carbines.

We disassembled the carbines and reassembled them numerous times over the course of the test. This allowed us to make Cerrosafe casts of the chambers.

We only fired one type of ammunition through each carbine. Different colors of Magpul MOE furniture made it easier to identify which rifle was which. Throughout the testing, we successfully avoided any “cross-contamination.” In other words, each carbine fired only the ammunition it was supposed to.

The carbine firing the Federal brass cased ammunition, serial number ARA041079, had standard black handguards and stock. The Brown Bear-firing carbine (LBM23712) had olive drab (green) furniture, and the Wolf (LBM21236)and Tula (LBM23157) carbines had flat dark earth (tan) furniture. For simplicity’s sake, we’ll refer to the weapons hereafter as “the Wolf carbine” or “the Federal carbine,” etc.

Initial Preparations

Visual Inspection

We broke each firearm down and inspected it to ensure it was within acceptable standards. Our initial visual inspection did not reveal any deficiencies we deemed serious enough to be addressed prior to the beginning of the test. During the first range trip, however, serious accuracy issues were noted with two carbines – the Federal and Brown Bear weapons.

Both rifles shot groups of over 5MOA, or over 5 inches at 100 yards, out of the box. We fired ten shot groups for all accuracy testing in this article. The results are not directly comparable with three or five shot groups. Because these groups were much larger than they should have been with any factory new ammunition, we examined the rifles.

Our team completely disassembled the upper receiver assemblies of the two problem carbines in order to determine the cause of this issue. We immediately saw the problem related to improper barrel nut torque values. The barrel nuts, which slide over a collar on the barrel and thread onto the front of the upper receiver, required less than 5 ft-lbs to break loose.

Proper torque values for this part are 30-80 ft-lbs. Once we properly reassembled the components, ten shot group sizes shrank to approximately 3.5 MOA. This is a realistic result to expect from standard carbines firing bulk ammunition.

Other Tests

Before we started high volume testing, we conducted other tests and observations in order to gather as much data as possible about performance. These tests include but are not limited to chronograph (velocity) testing, Cerrosafe measurements of internal chamber and bore dimensions, chamber and gas port pressure testing, and high speed video of bolt velocities and cycle times.

We conducted these tests periodically throughout this project. Our team measured accuracy and velocity every 2,000 rounds and Cerrosafe at 5,000 and 10,000 rounds. We fired these rifles mostly at a very fast pace. It was not unusual for our test team to fire up to ten magazines (300 rounds) in a row. Of course, we did slow our rate of fire at times, especially when accuracy testing was being conducted. However, we kept the rates of fire consistent across all rifles – if we fired one quickly, so were the others.

Although the shooting was fast and hectic, we did not exceed certain temperature and rate of fire limits. The barrels did not exceed 750 degrees Fahrenheit. Firing was periodically halted to identify the cause of a malfunction, conduct diagnostic tests, or replace parts.

Cleaning and Lubrication

We followed a strict cleaning and lubrication schedule.

At 2,500 and 7,500 rounds, we wiped down the bolt carrier group with a paper towel. At 5,000 rounds, we gave each rifle a detailed cleaning. We applied a single drop of FireClean lubricant to the cam pin hole of the bolt carrier group every 1,000 rounds, and used six drops after each of the aforementioned cleaning intervals.

Certain small parts were replaced as needed, and they will be discussed later in the article. After all initial tests were complete, the bulk of the shooting commenced.

Brass vs. Steel Cased Ammo Results

Which Ammo Was Most Reliable?

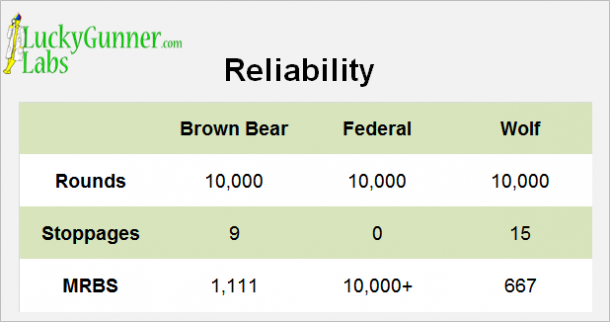

The data which will probably be most interesting to everyone who reads this article is how often each rifle malfunctioned. To satisfy that particular thirst, here are the basic results:

- Federal: 10,000 rounds, 0 malfunctions.

- Brown Bear: 10,000 rounds, 9 malfunctions (5 stuck cases, 1 magazine-related failure to feed, 3 failures to fully cycle)

- Wolf: 10,000 rounds, 15 malfunctions (stuck cases)

- Tula: DNF (6,000 rounds in alternate carbine, 3 malfunctions)

The carbine firing Tula had a case stuck in the chamber after 189 rounds. This proved exceptionally difficult to clear, even with the use of a steel cleaning rod after the rifle had cooled. Over the next three hundred rounds, we encountered 24 malfunctions total. These problems consisted of stuck cases and failures to fully cycle, or “short stroking.” At this time, we pulled the Tula carbine from the testing. The delays caused considerable problems and put the entire project’s completion in peril.

We decided to fire the remainder of the Tula ammunition through other carbines. We cycled approximately 300 rounds through an HK416 (no malfunctions), 1,000 through a Spike’s Tactical carbine (3 malfunctions), and 6,000 through a Spike’s Tactical midlength without any cleaning (3 malfunctions). Stuck cases or failures to eject accounted for all those malfunctions.

Of the remaining three ammunition brands, the first malfunction encountered was a magazine-related failure to feed at 2250 rounds with the Brown Bear carbine. For the Wolf carbine, the first malfunction occurred at 4850 rounds – a stuck case.

We conducted this testing in the Arizona desert during monsoon season. Dust storms frequently interrupted our range trials. These storms covered the carbines in fine sand and we also saw rainstorms drench the carbines in water. These storms did not affect the previously set cleaning schedule. In addition, we shot at a high rate of fire. We fired the carbines until they were too hot to touch at times during the test. These rates of fire were identical for all weapons and they continued to function very well despite the adverse conditions.

Cleaning Schedule & Changing Parts

At the 5,000 round mark, we cleaned the bolt carriers, upper receivers, and barrels. After we noted inconsistent cycling thanks to the aid of high speed video, we replaced the action springs ($3). We also pulled out and replaced the extractor springs ($6.99) and gas rings ($2.19).

The second half of the test started off with short stroking malfunctions from the Brown Bear carbine. This occurred at 5,200 and 5,250 rounds. High speed video showed that the bolt was barely coming back far enough to pick up the next round. It occasionally wouldn’t travel far enough to eject the spent case. Additional lubrication did not prevent the second malfunction.

A detailed physical examination revealed previously unnoticed carbon buildup in the gas key and gas tube which had almost completely occluded those components. We inspected the other firearms. We didn’t see carbon buildup that was remotely close to that of the Brown Bear carbine. It was difficult to clean these components in the field. So, we decided to them aside in order to examine the phenomenon.

We replaced the gas tube and bolt carrier of the Brown Bear rifle with identical components. After the swap, we resumed firing without incident.

No malfunctions occurred until 7,500 rounds. We ran into five stuck cases between 7,500 and 8,200 rounds. From 7,500 rounds on, we observed a number of cases with distended and/or split necks.

The last malfunction with Brown Bear was a cycling issue similar to the first two. This happened at the 9,551 round mark. A change in report and recoil indicated that the round was possibly undercharged, although the projectile did exit the bore.

We encountered two more stuck cases with the Wolf carbine at 5,800 and 5,850 rounds. We didn’t take actions and didn’t get another stuck case until the round count passed the 9,000 mark. From 9,200 to 10,000 rounds, we observed twelve stuck cases. During this time, we used a Boresnake to superficially clean the bore and chamber. It did not appear to have any impact on the occurrence of malfunctions.

As stated previously, the carbine firing Federal ammo functioned flawlessly from the first round to the last. There is not much else to report in terms of reliability. It just worked.

The table below summarizes the reliability of each manufacturer’s ammunition as well as mean rounds between stoppages (MRBS).

Is Brass or Steel Cased Ammo Dirtier?

Of particular concern to some shooters is whether or not one type of ammo is dirtier than another. Shooters often malign imported ammunition for being dirty and difficult to clean. So, we didn’t clean lower receivers of each firearm at all from the first shot to the last, in order to see which became the most filthy.

We paid special attention to how much effort it took to clean each rifle at the 5,000 round detailed cleaning portion of the test. Here, you can peruse high-resolution photos of the lowers.

[tilezoom zoomlevel=”10″ zoomfile=”lowersh” caption=”This photo allows you to zoom in and see the filthy lower receivers.”]1 2 3 1 2 3[/tilezoom]

Interestingly, the dirtiest lower receiver was that of the Federal carbine. It took us significantly longer to clean the upper receiver and bolt carrier group assembly of the Federal carbine than the Brown Bear and Wolf carbines. Although you should keep in mind that carbon fouled the Brown Bear carbine’s gas tube and gas key so much after 5,000 rounds that it would no longer function reliably. We observed nearly the same level of buildup on the replacement key and tube after they fired just short of 5000 rounds.

[tilezoom zoomlevel=”10″ zoomfile=”lowersb” caption=”Another close up view of the the AR-15 lower receivers used in the test.”]1 2 2[/tilezoom]

How was Accuracy Affected?

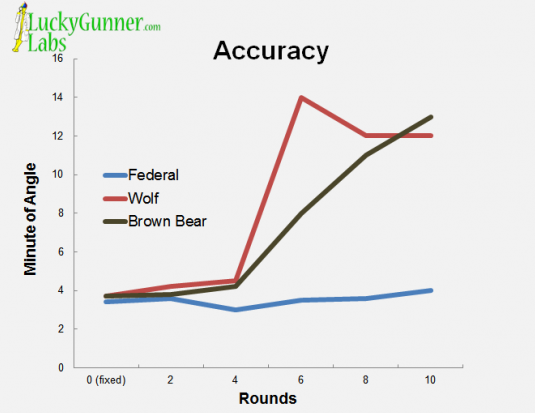

End users of off-the-shelf carbines firing bulk ammo should never expect tack-driving accuracy. That said, we checked group sizes every 2,000 rounds in order to monitor how each type of ammunition fared. Again, these groups consisted of 10 shots at 50 yards from a supported position, using a US Optics scope at 17x magnification.

While the carbine firing Federal ammunition maintained acceptable accuracy up to and including the 10,000 round mark, the Brown Bear and Wolf carbines exhibited significant accuracy loss by the 6,000 round mark. It is quite possible that this first started occurring earlier than 6,000 rounds, because groups at 4,000 were well within standards of 5MOA or less, while some shots at 6,000 “keyholed,” or impacted the target sideways.

Even if we use accuracy as the only factor to determine serviceability, the Federal carbine was by far the best performer in this category. Its barrel was showing wear, but was serviceable right up to the end of the test. The Brown Bear and Wolf barrels would have required replacement at approximately 5,000 rounds, or halfway through the test.

To see accuracy results for each manufacturer at specific intervals of the testing, click through the slideshow below:

[galleria id=”72157632435427504″][/galleria]

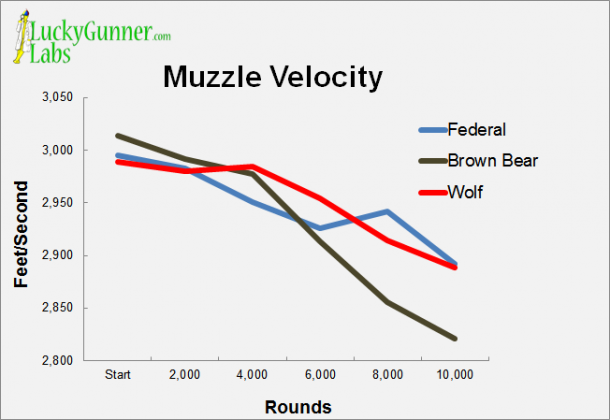

Were There Velocity Changes?

In addition to accuracy data, we have chronograph data at 2,000 round intervals. Velocity loss is another sign of a barrel becoming worn out, or “shot out.” However, in this case, it was not an exceptionally reliable indicator of barrel failure, for the Wolf and Federal velocities were fairly close to one another all the way to 10k, while the Brown Bear velocity did decrease in a more significant manner towards the end of the test. A military standard for a barrel being unserviceable is a drop in velocity of 200fps or more.

Data Analysis

While the above section is essentially a factual summary of the events which occurred during testing, the following is a logical explanation for the results of the test. This explanation is based on our experiments/measurements/observations as well as the work of other individuals and organizations in the field.

Why Didn’t Tula Function Well in the Test Carbine?

One of the first questions one might have after reading the above treatise is, “What happened with Tula?”

After all, it consists of a 55 grain bimetal jacketed lead core projectile loaded in a polymer coated steel case. This description is by no means an outlier compared to the other ammunition in the test. In terms of velocity, Tula was also in line with the other products. Tula functioned very well in a Spike’s Tactical midlength, which saw 6,000 rounds of Tula without any cleaning and only had three malfunctions.

But in the Bushmaster carbine, Tula was a no-go. In terms of functional problems, there were two major issues with Tula: “short stroking” – a failure of the bolt to fully cycle to the rear – and extraction problems. Further research and experimentation indicated that there was likely one factor which contributed to both failure types.

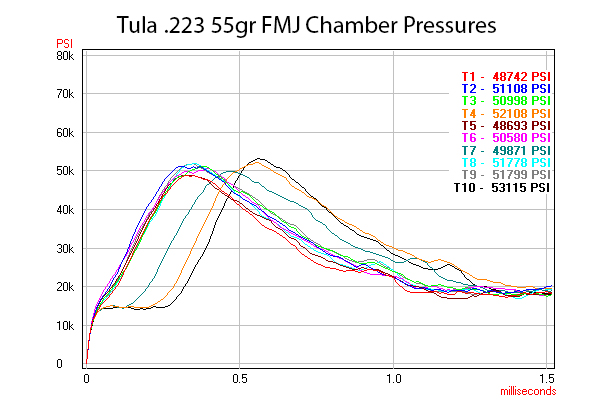

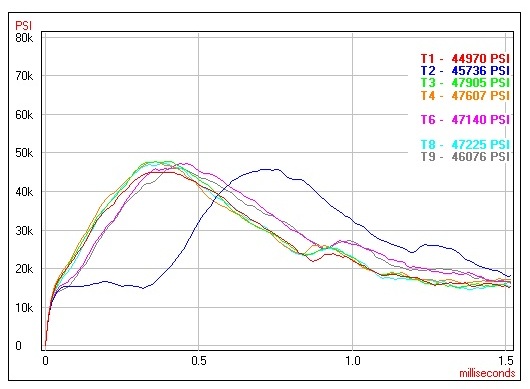

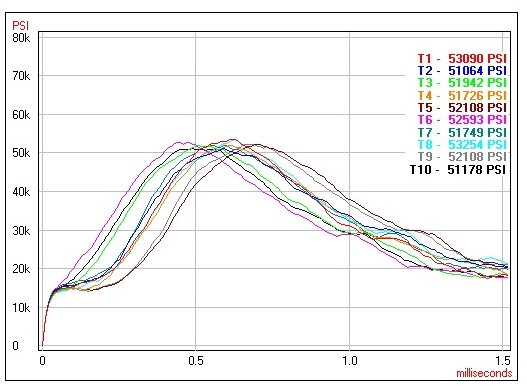

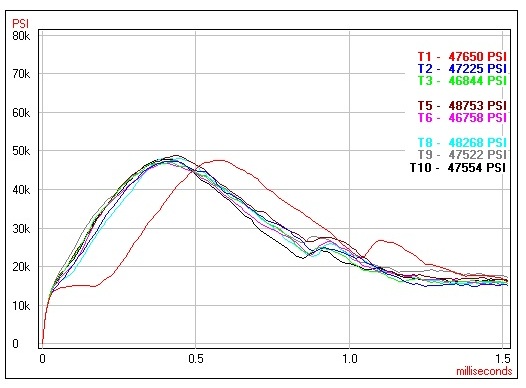

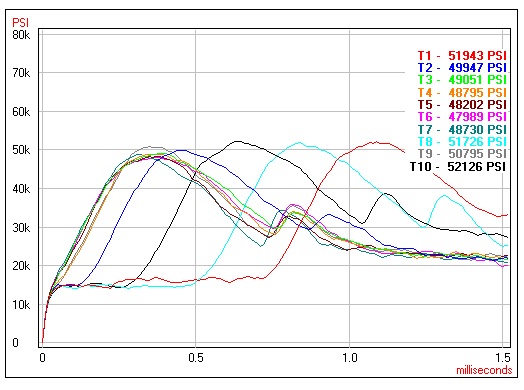

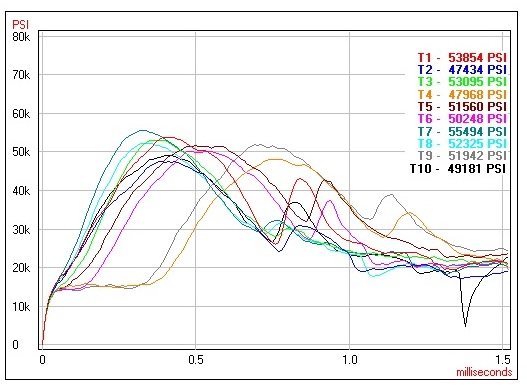

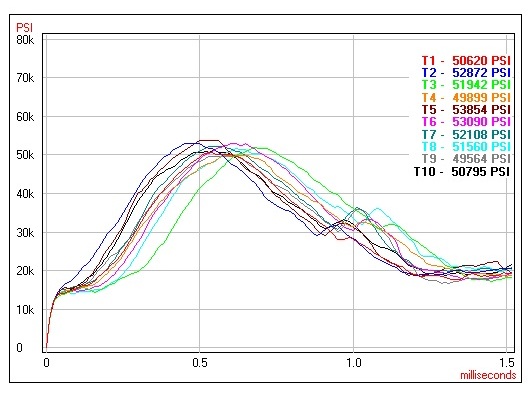

Chamber pressure measurements indicated Tula had the second highest chamber pressure of any ammunition in the test when all barrels were new.

We verified these results by using a separate test barrel for all ammunition types. Federal was highest with a maximum average pressure of 52kpsi and Tula followed with 51kpsi. Wolf registered 47.5kpsi with Brown Bear close behind at 47kpsi.

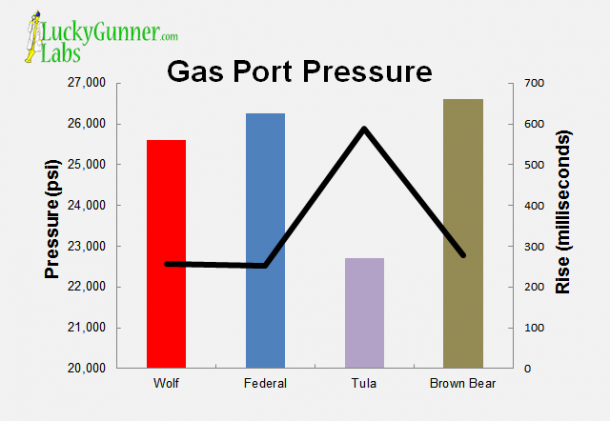

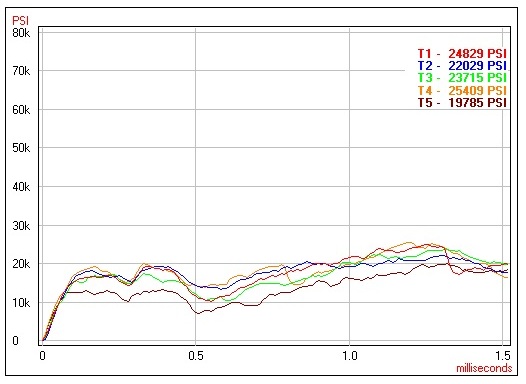

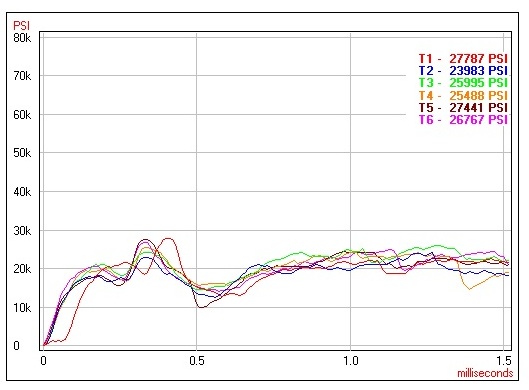

Powder Burn Rate & Gas Port Pressure

What’s really important in this case, however, is not the maximum chamber pressure number, but powder burn rate and thus gas port pressure. Whether measured in clean, fouled, new, or worn out barrels, Tula exhibited gas port pressures that were 10-20% lower than all other ammunition types.

Basically, the powder burns too fast, and by the time the bullet has reached the barrel, the pressure drops. The rise time of Tula, defined as the time in microseconds for pressure to rise from 25% to 75% of maximum chamber pressure, is 175ms. In comparison, Federal AE223, depending on temperature, has a rise time of 260-300ms.

Couple this with the .058″ gas port Bushmaster rifles use – about the same as a Colt 6920 with a 16″ barrel, and just about the smallest gas port you’ll see on any 16″ carbine AR-15, and you’re bound to encounter problems. The Spike’s Tactical midlength did not have a small gas port relative to its longer gas system, and so it functioned without any short stroking issues.

This explains the short stroking issues, for an insufficient gas port pressure for a given gas system length and port diameter would logically cause insufficient bolt velocity – but what about the failures to extract?

Heating Brass vs Steel

Part of the answer to this question is the nature of the case material itself. When heated, steel does not expand and contract the same way that brass does – in fact, brass expands 1.5 times as much as steel. The shape of the .223/5.56 case was designed with brass as the case material; this plus the fact that steel doesn’t expand – and more importantly, contract – like brass means that extraction will be naturally more difficult.

Beyond these differences, though, is it possible that adjusting the pressure curve could make extracting Tula – and possibly other ammo – easier?

A clever test conducted by the US Army’s TACOM and presented at NDIA in 2003 may have the answer. Titled “Understanding Extractor Lift in the M16 Family of Weapons,” the test concluded that the extractor lifts off the rim of the case during initial rearward travel, but that residual chamber pressure holds the case against the bolt face until the extractor returns to the case rim.

In other words, if there are pressure curve issues, case extraction – that steel casings make slightly more difficult – becomes questionable. The extractor may not return to place in time to pull the case out of the chamber. While a drop in Tula’s chamber pressure at the appropriate time is not observed, it is possible that the location of the gauge is not ideal for reading pressures against the bolt face.

We know from the rise time and gas port data that the powder does burn too fast for the system. So, it is quite likely that this is a contributing factor to the rate of extraction failures.

To be sure, the short stroking failures are a result of low gas port pressure, which is due to a powder burn rate not perfectly matched to that which would be ideal for the AR-15 platform. If you aren’t sure if this ammunition will cycle in your AR-15, buy a few boxes and shoot one round at a time from an otherwise empty magazine. If the bolt does not consistently lock back to the rear, chances are that you will encounter problems with this rifle/ammunition combination.

What Effect Do Coatings Have On Steel Cased Ammo Performance?

A common belief is that the lacquer coating of certain steel cased ammunition will “melt” in the chamber of a hot rifle and cause subsequent rounds to fail to extract. At one point, we might have believed that.

But in this test, we saw three times as many failures to extract with the polymer coated Wolf brand ammo (15 extraction failures) than with the lacquer coated Brown Bear ammo (5 extraction failures). Although we fired the polymer coated Tula ammunition in different rifles, the rate of extraction failures in those rifles was lower than that of Wolf.

If anything would make that lacquer coating “melt,” it would be the treatment these rifles received during the test. We shot them until they were too hot to hold – hot enough that a chambered round would cook off in ten to fifteen seconds. We also tried leaving rounds chambered before temperatures reached that point. None of this harsh treatment caused extraction problems.

We found no evidence to back up the claim that lacquer coatings melt in the chamber and cause extraction failures.

Why Did The Barrels Wear The Way They Did?

Certainly one of the most visually striking parts of this article is the inclusion of post-test barrel cutaways. We cut the barrels axially with an angle grinder and then longitudinally by the wire EDM process. This lets us see exactly how the barrels wore throughout the test. There were significant differences.

The first answer to this question is, “Because we shot them until they got hot, and then we kept shooting them.”

The rate of fire definitely contributed to rapid barrel wear. Still, tother factors played a major role.

[tilezoom zoomlevel=”10″ zoomfile=”chambers” caption=”These tight images of the barrel cutaways offer insight into barrel wear.”]1 2 3[/tilezoom]

Bimetal Jacket Impact

As indicated by accuracy testing, the steel cased/bimetal jacketed ammunition caused accelerated wear to the inside of their respective bores.

The barrel of the Federal carbine had plenty of life left after 10,000 rounds at extremely high rates of fire. We subjected the Wolf and Brown Bear barrels to the same rates of fire and they were completely “shot out” by 6,000 rounds.

At the end of the test, the chrome lining of the Wolf and Brown Bear barrels was almost gone from the throat forward. The barrels had effectively become smoothbores, with the rifling near the muzzles acting only as a mild suggestion on the projectiles. A throat erosion gauge could be dropped into the bore from the muzzle end with absolutely no resistance.

The bottom line is that for both Brown Bear and Wolf, the lands had been completely ground down to the diameter of the grooves. The differences in material are still visible, the grooves have some chrome lining left. You can easily see longitudinal scratches inside the bore. We believe they were caused by the projectiles meandering their way down the bore in a casual manner before exiting and tumbling in a fairly random direction.

[tilezoom zoomlevel=”10″ zoomfile=”gasports” caption=”A detailed look at gas port erosion for each of the ammunition manufacturers tested.”] 1 2 3[/tilezoom]

Gas Port Erosion

The gas port of the Federal carbine was far more eroded towards the muzzle than the Wolf or Brown Bear barrels. I believe this is due to the excessive throat erosion and barrel wear of these two barrels. The Federal barrel maintained a good seal between itself and the bullet up to 10,000 rounds. Meanwhile, the Wolf and Brown Bear barrels let a significant amount of gases past the projectile. This reduced the flame-cutting effect on the gas port as time went on.

The steel cases themselves don’t have any effect on the condition of the bore. The difference lies with the projectile. The soft copper jacket of the Federal ammunition simply doesn’t cause the same amount of wear as the bimetal (copper and steel) jacket of the Russian ammunition.

We continued firing for the Wolf and Brown Bear carbines after shooting out their barrels in order to collect other data and finish the test. However, we stopped firing the Tula at 6,000 rounds from the backup Spike’s Tactical midlength.

The data from this weapon cannot be directly compared to the others. This is due to differences in construction (the barrel had a midlength gas port, Spikes manufactured via the hammer forging process, and it features “extra thick” chrome lining) and methodology (We fired it with only reliability testing in mind and saw even higher rates of fire as well as environmental abuse such as mud, water, and dirt testing). Still, we can draw general conclusions from these results, even if direct comparisons cannot be made.

The barrel of the Spike’s Tactical midlength shot acceptable groups at 4,000 and 5,000 rounds, after it saw seventeen magazines of 30 rounds dumped through it several times. However, by 6,000 rounds, it too was keyholing. The changes in barrel construction did not appear to offer a massive advantage in terms of barrel life, while changes in ammo – to copper jackets only – did. Performance indicators for the Federal barrel show that it would likely have remained serviceable for at least another three to five thousand rounds when it was sectioned after 10,000.

An important factor to consider is that in the real world, barrels are wear items. They will eventually become unserviceable if you shoot enough. If you plan on shooting a lot, don’t get too attached to your barrel – think of it as a thing that does a job for a certain period of time at a certain cost. When that time is up, change the barrel. The AR-15 is a modular platform, and barrel changes are quite simple.

Think of it this way – if a barrel A costs 50-100% more than barrel B but only delivers the same level of accuracy for 0-50% more time, isn’t it a more financially sensible decision to shoot through more examples of barrel B?

The high speed video below offers a comparison of each firearm’s cyclic rate as testing continued.

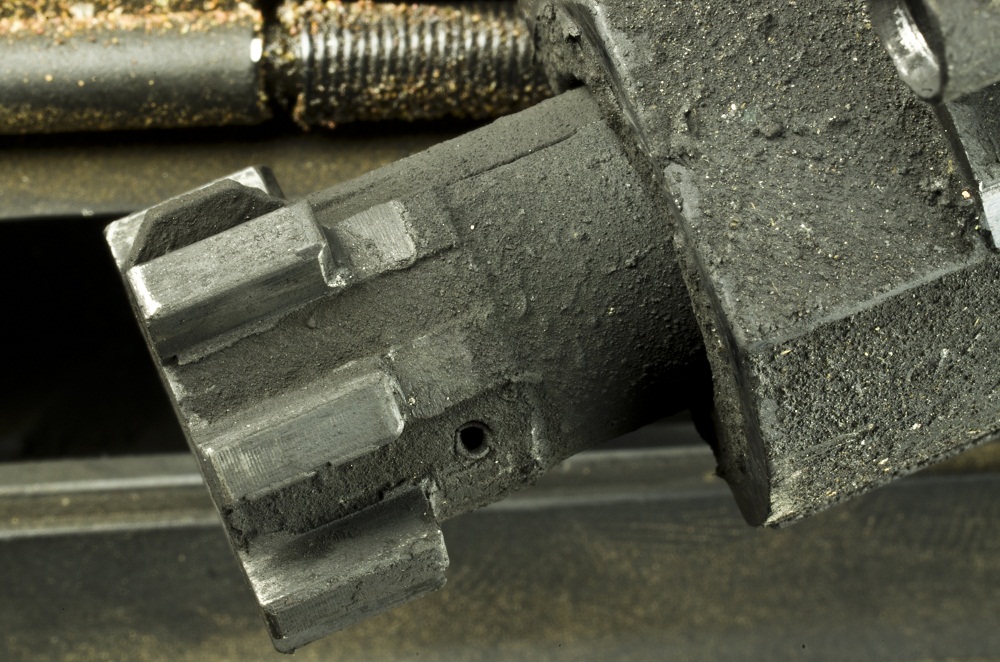

Did The Steel Cases Break or Wear Down The Extractors?

We noticed different wear patterns on the extractors after 10,000 rounds had been fired. Given that most of the extraction failures with the steel cased ammunition brands occurred during the last half of the test, it is possible that a replacement of the extractors at the halfway point or later would have reduced the number of failures to extract. While you couldn’t observe these wear patterns with the naked eye, macro photography made them obvious.

[tilezoom zoomlevel=”9″ zoomfile=”extractors” caption=”The image above lets you zoom in to see the extractors in great detail.”]

1

2

3[/tilezoom]

If you regularly shoot steel cased ammunition, it might be a good idea to replace your extractor along with your barrel, or at 5000 rounds, whichever comes first. Replacement extractors are not very expensive. Changing the extractor spring at the same time doesn’t require more work – just set aside the old extractor and spring assembly and install the new one after popping the new spring into place in the new extractor.

You should replace average OEM extractor springs beginning at 2,500 rounds and no later than 5,000. Better extractor springs will not require such frequent replacement with any ammunition – the Colt “Gold” extractor springs used in each rifle starting at 5,000 rounds were still providing reliable extraction at the 10,000 round mark, and would not have required replacement after 5,000 rounds.

Which Ammo To Buy

If Federal Brass Cased Ammo Performed So Great, Why Bother Buying Steel Cased Ammo?

The performance of the carbine firing Federal ammunition in this test was undoubtedly impressive. We fired approximately 412 pounds of ammunition with very minimal maintenance in austere conditions without a single malfunction. The fact that the rifle remained serviceable and combat accurate from the first shot to the last – could hardly be improved upon. To many who read this report, this is all the justification they need to purchase this type of ammo.

To others, the increased cost of brass cased ammunition isn’t worth it. After all, the Wolf and Brown Bear ammo had very few malfunctions, all things considered. Plus, let’s be honest – in all likelihood, most people will never shoot 10,000 rounds through their AR-15. We’d be excited as a company if they did, but we used these rifles far beyond what is likely to be encountered in the real world. So, for many consumers, this test will be justification that buying steel cased ammunition is a sensible decision. In many cases, it is.

Is Brass or Steel Cased Ammo More Cost Effective?

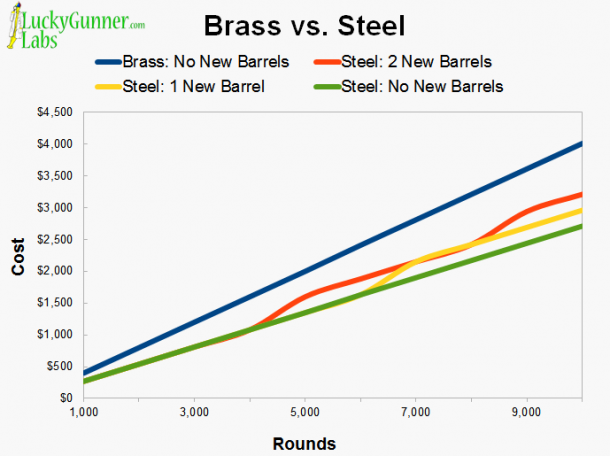

Although ammunition prices are volatile, the prices of brass and steel remain similar to one another. That is, brass is generally more expensive than steel. We created a chart comparing the cost over time of each type, including ammunition and spare parts replacement costs.

The difference in price between brass and steel cased ammo (more specifically, copper jacketed and bimetal jacketed) means that you’ll have plenty of savings with which to buy new barrels – even if you shoot so fast that you replace them every 4,000 rounds. For this chart, we calculated brass ammunition at $130 per thousand higher than steel and replacement barrels at $250 apiece.

The final decision is up to you, but now that you know some facts, you can make a better-informed decision in the brass vs. steel cased ammo debate.